Western Talc Mine (main ore body) and Dunn Mill near Tecopa, San Bernardino County

The Western Talc mining complex was once one of the largest talc operations in the Death Valley region. Talc proved to be one of the area’s most valuable resources. This is often a surprise to people who hear the stories of the lost silver and gold mines but the economics of talc were often better than gold and silver because talc was abundant, easy to mine, and had consistent demand across a wide range of industries. Unlike gold and silver, which required costly and complex extraction and refinement processes, talc deposits were often surface-exposed and could be mined with relatively simple techniques, significantly reducing production costs. Additionally, talc had stable, non-speculative demand driven by its use in ceramics, paints, plastics, paper, and personal care products, ensuring a steady market. In contrast, gold and silver were subject to volatile prices influenced by market speculation and economic trends, making talc a more reliable and economically viable resource in many areas.

A significant belt of talc deposits extends approximately 70 to 75 miles across southern Death Valley, from the southeast slope of the Panamint Range eastward into the Ibex Spring and Kingston Range region. This belt encompasses several mountain ranges, including the Panamint Range, Owlshead Mountains, and Silurian Hills. Notable talc deposits within this area are found in Warm Spring Canyon, Galena Canyon, the Alexander Hills, and the eastern Kingston Range. The Warm Spring Canyon deposits, for instance, were mined continuously since the 1920s ending only in the 1980s. These talc-rich formations have been significant sources of high-grade talc, contributing to various industries over the years.

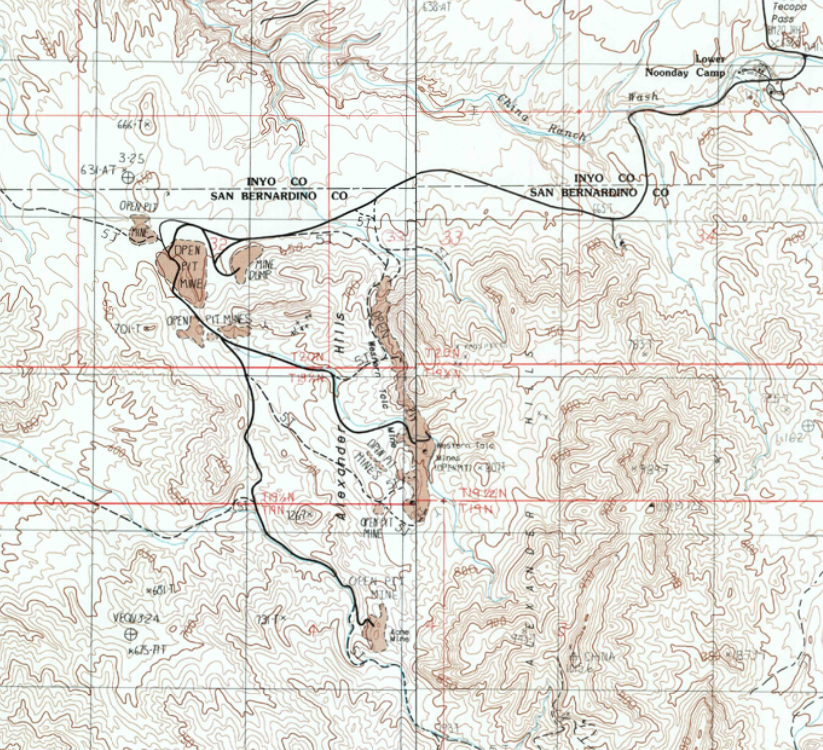

The Western Talc Mine is a former talc-steatite mine located in Sec. 4, T19N, R8E, SBM, 1.1 miles NNW of the Alexander Hills, in the middle of the hills. Local rocks include Precambrian rocks, undivided, unit 1 (Death Valley).

Workings include a rather poorly defined open pit that includes multiple benches (the topo map reflects a huge shaded area, trending N-S at over a mile long). There are are several smaller (relatively speaking) open pit mines, all labeled "Western Talc Mine." In addition, we observed examples of underground mine workings (drifts and winzes) that have been cut through by the later open pit methods and remains of surface adits and shafts that were from the early phases of accessing the ore body.

History of the Western Talc Mine

The first major talc strike in the Alexander Hills was the Western Talc Mine (under which the other adjacent mines were eventually consolidated). It was first developed in 1912 by Lycurgus Lindsay, who dubbed himself the “Talc King” borrowing the style of Frank "Borax King" Smith. Lindsay, who had already made his fortune speculating in Mexican copper mines, sought talc for his pottery businesses, which produced wall tiles and sewer pipes.

In 1909, Lindsay purchased a group of claims called the Talc Mine, originally discovered a year earlier by the owner of nearby China Ranch and his partners. By 1912, Lindsay was hauling wagonloads of talc daily to the Tonopah & Tidewater Railroad for transport to his factories.

The mine’s early years saw modest returns, with less than 1,000 tons shipped in 1912, valued at $10 per ton. However, production steadily increased, reaching 5,000 tons at $15 per ton by 1915. Lindsay aggressively expanded operations, producing 12,000 tons in 1920 and generating roughly $500,000 in total revenue.

Despite the mine’s success, Lindsay overextended himself financially (there were allegations of fraud), and his business collapsed in 1921. The mine changed hands several times and in 1928 it was acquired by the Western Talc Company which was by far the largest and most stable operator.

Mining at the Western Talc continued until 1975 and shipments of stocked ore were still going until the 1980s. Over its lifespan, the mine produced more than 300,000 tons of high-grade talc, valued at several million dollars, cementing its place in the history of the Death Valley region.

Looking down into the small pit from the last photo. On the fourth bench down, just below the green sunspot on the lens, look for the collapsed drift from the early underground mining activities here. Then a closeup on the collapsed drift. The next shot shows the contact between the talc ore body and the adjacent bedrock. Finally, a shot looking into the pit from the dump truck access road.

Low grade steatite ore compromises the majority of the waste piles. What looks like an old collapsed magazine for explosives. An overview of the upper bench and top of the massive waste rock pile.

A detail view showing the talc-steatite ore body under the layers of Precambrian age (157.3 - 703 million year old - the younger ones are above the talc and the older ones below) rocks that were formed when this was still all the ocean.

At the edge of the waste rock pile was a collapsed collar for a vertical shaft that went down through the waste rock to access the ore body. It must've been very high grade to warrant such an unusual configuration to mine vertically through the open pit while both were operating. The wife is standing near where the ore cart track dumped off the edge.

Looking down into the central part of the mine. That pile in the center is just raw steatite that never got shipped. Close up on that ore bin.

From that ridge above the ore bin, the mine keeps going! Down in that small valley is the remains of the modern mill named the Dunn Mill according to records. This was the mill that ran through the 1970s and 80s - something you can ascertain based on the cement work.

Remains of the modern Dunn Mill. The separators were for ore sorting. The recessed area carried the conveyer belt mechanisms. Note the debris diverter in the wash to protect the conveyer supports. Finally looking down into the pit from the dump platform where the trucks unloaded into the processor.

That's all for this one. Stay tuned for another edition where I explore the Acme Mine and the other open pits and underground workings that make up this massive talc operation.